2022 China New Design Ammonia Ice Flake Evaporator - CE certificate 5ton/day Ice Flake Evaporator/Ice Plant – Icesnow

2022 China New Design Ammonia Ice Flake Evaporator - CE certificate 5ton/day Ice Flake Evaporator/Ice Plant – Icesnow Detail:

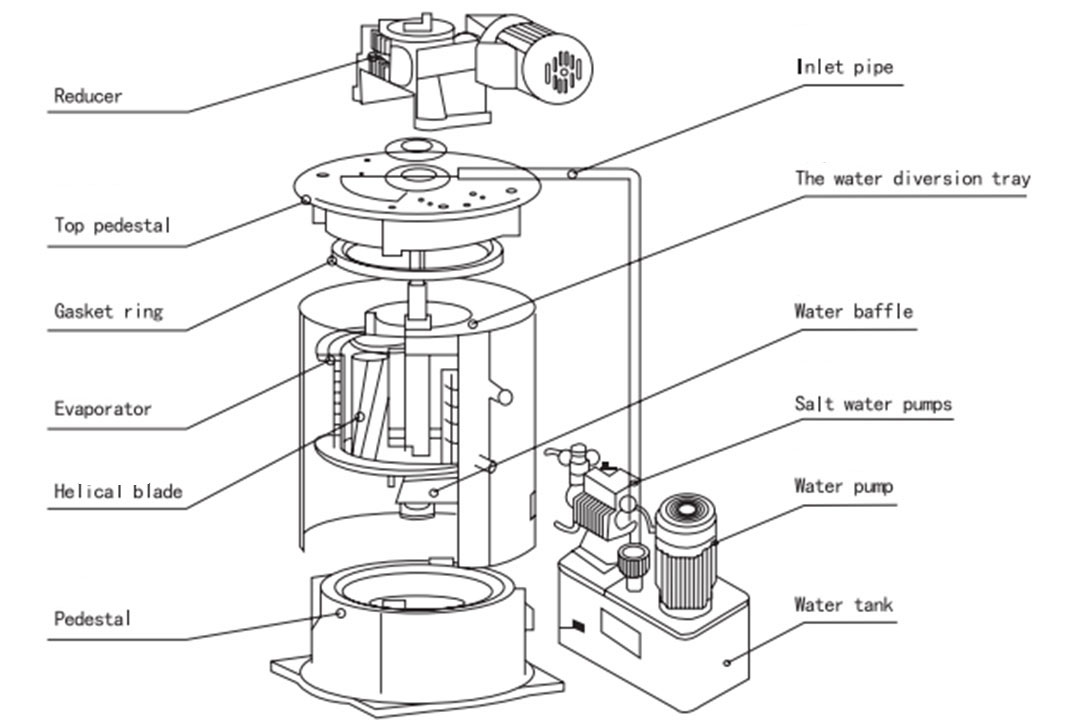

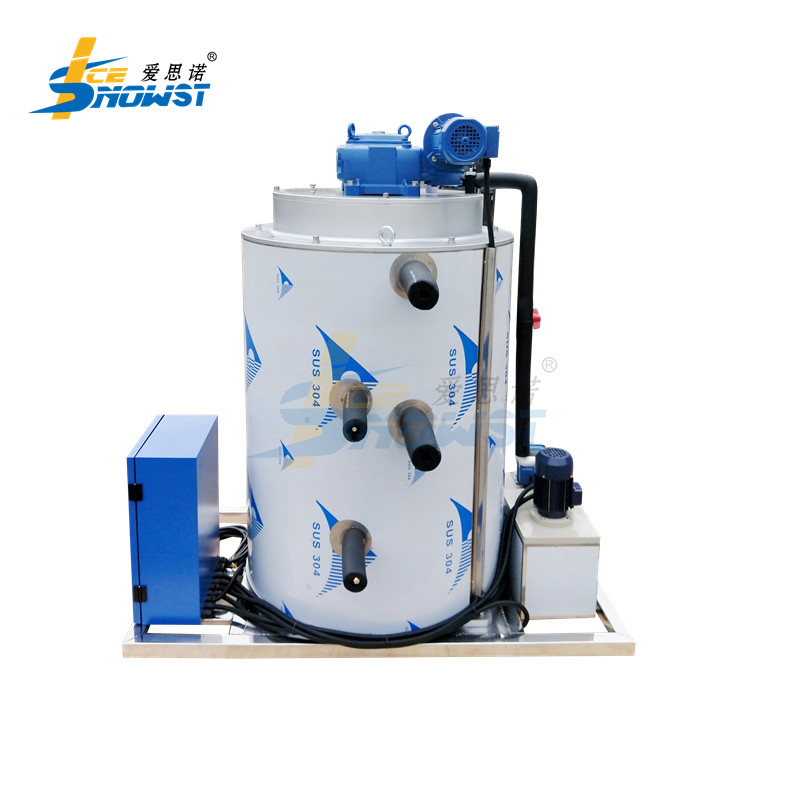

The evaporator with fixed vertical design is made of SUS304 or carbon steel with high heat transfer efficiency and surface Nobelium electroplated. And the automatic protection welding equipment and annealing heat treatment furnace ensure the ice machine high quality and better performance.

Flake ice machine evaporator are widely applied into flake ice making plant and ammonia system ice machine, etc. To realize the continuous ice making, users only need to connect the evaporator tube to the refrigeration source, convenient installation, lower cost.

| No | Name | Technical Data | |

| 1 | Capacity | 5000Kg/24h | |

| 2 | Refrigerant gas | R22/R404a/R507a or Other as your required | |

| 3 | Supply voltage | 380V/50Hz,3P/220V/60Hzor other | |

| 4 | Size | 1500*890*1590MM | |

| 5 | Evaporating temp | -20℃ | |

| 6 | Condensed temp | 40℃ | |

| 7 | Material of flake ice evaporator | Carbon steel chrome Or SUS304 | |

| 8 | Power | Circulating water pump | 0.18 KW |

| Reducer motor | 0.37KW | ||

1. Be made of low-temperature pressure vessel special materials and passed precision processing;

2. More sufficient evaporation area and better performance with dry style evaporation way;

3. Whole processing is made by vertical lathe to ensure the precision up to 2 ounces;

4. Be designed and produced with standard low-temperature pressure vessel manufacturing process, including surface treatment, heat treatment, gas-tight test, tensile & compression strength test, etc.

5. Using imported refrigeration accessories;

6. All water supply line are made of stainless steel, high sanitary condition;

7. Fast ice forming & falling speed, ice begins within 1 to 2 minutes

1. Fishing:

Sea water flake ice machine can make ice directly from the sea water, ice can be used in fast cooling of fish and other sea products. Fishing industry is the largest application field of flake ice machine.

2. Sea food process:

Flake ice can lower the temperature of cleaning water and sea products, therefore it resists the growth of bacteria and keeps the sea food fresh.

3. Bakery:

During the mixing of flour and milk, can prevent the flour from self raising by adding flake ice.

4. Poultry:

Huge amount of heat will be generated in food processing, flake ice can effectively cool the meat and water air, also supply moisture for the products at the meantime.

5. Vegetables distribution and fresh-keeping:

Now days, in order to guarantee the safety of food, such as vegetables, fruit and meat, more and more physical methods of storing and transporting are being adopted. Flake ice has a fast cooling effect so as to ensure the applied object will not be damaged by bacteria.

6. Medicine:

In most cases of biosynthesis and chemosynthesis, flake ice is used to control the reaction rate and maintain the liveness. Flake ice is sanitary, clean with rapid temperature reduction effect. It is the most ideal temperature-reducing carrier.

7. Concrete cooling:

Flake ice is used as the direct source of water in concrete cooling process, more than 80% in weight. It is a perfect mediator temperature controlling, can achieve effective and controllable mixing effect. Concrete will not crack if has been mixed and poured inconstant and low temperature. Flake ice is widely used in the large projects such as high standard express way, bridge, hydro-plant and nuclear power plant.

1. Cheaper price – more competitive.

2. Longer warranty period – longest up to 18 months.

3. Faster delivery speed, have stock for specification under 5tons

4. Superior after-sales service guarantee & professional technical support.

5. More stringent quality assurance than foreign trade company, passed CE, SGS and BV world-famours three main certification

6. And the most important: As one of few ice machine evaporator leading and professional manufacturers who have the self-production capacity, we provide it for many refrigeration companies and counterparts. And they just need to assemble the ice machine with our flake ice evaporator and other refrigerating accessories. our flake ice evaporators are warmly welcomed at home and abroad.

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for 2022 China New Design Ammonia Ice Flake Evaporator - CE certificate 5ton/day Ice Flake Evaporator/Ice Plant – Icesnow , The product will supply to all over the world, such as: Bahrain, Iran, Seychelles, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.