2022 Good Quality Ice Making Flake Ice Drum - convenient installation Ice Flake Evaporator 20Ton/day – Icesnow

2022 Good Quality Ice Making Flake Ice Drum - convenient installation Ice Flake Evaporator 20Ton/day – Icesnow Detail:

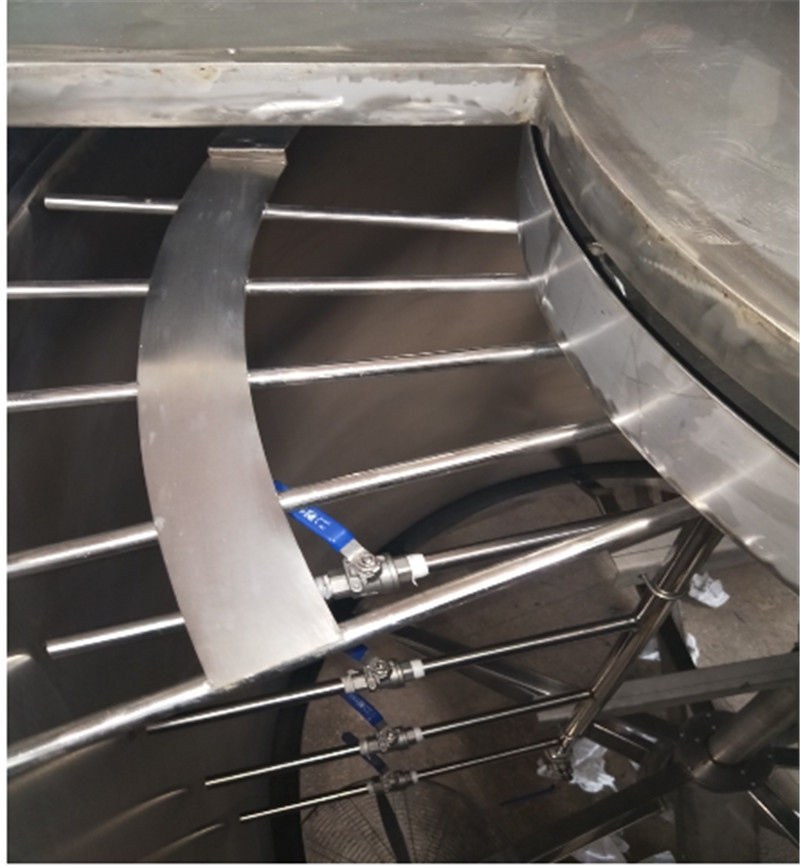

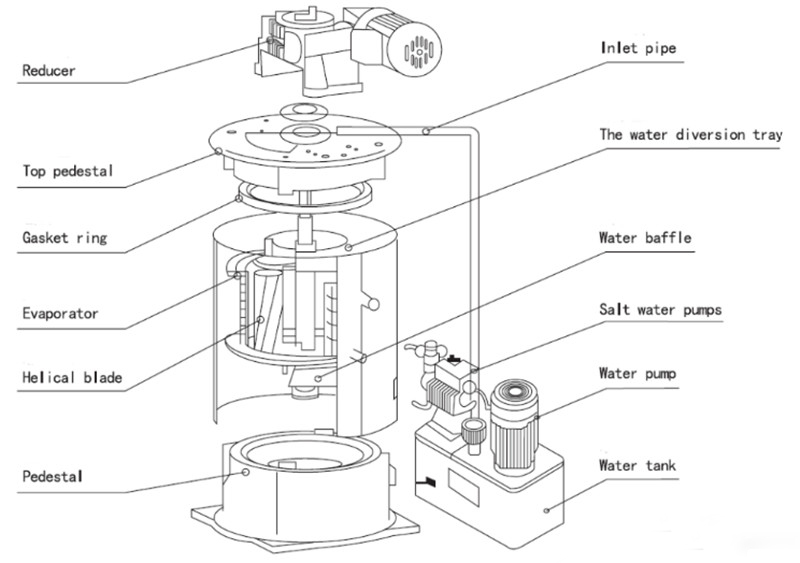

(1) Ice blade: made of SUS304 material seamless steel tube and formed through only one time process. It is durable;

(2) Spindle and other accessories: made of SUS304 material through precision machining, and conform to food hygiene standard;

(3) Thermal insulation: foaming machine filling with imported polyurethane foam insulation. Better effect.

(4) Evaporator size and installation direction can be customized according to customers requirements

(5) The material of evaporator wall, up and down pedestal is available (SS304 & SS316).

(6) stainless steel water tank, stainless steel for support base, stainless steel watch window, stainless steel ice cutter, stainless steel principle axis, stainless steel water distributing tray, stainless steel water connecting tray.

(7) we used C & U brand bearing, which is Japan brand, other supplier used very cheaper price bearing that from China, the quality is bad.we used SKF oil seal, which is good brand, it can use at -35degree.

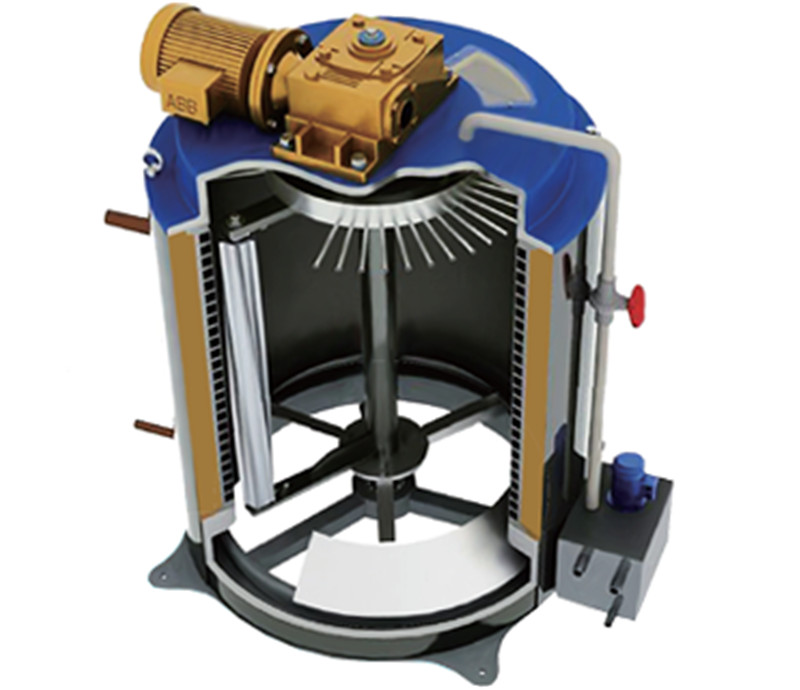

Professional evaporator producing plant, various horizontal lathes are all owned In Icesnow company. And the 3meter diameter vertical lathe can process the single flake ice evaporator work piece up to 60 tons. The high-performance annealing heat treatment equipment can eliminate the welding stress with its 850℃ high temperature annealing treatment ability, which can guarantee flake ice evaporator good material mechanics performance and prevent the evaporator inner wall from deformation forever.

Our spiral ice blade researched & developed and produced by ourselves independently is made of high performance strong stainless steel and formed through only one time process. Its scientific structure, clean hygiene, reasonable spiral angle and accurate cylindricity make it cut ice with less resistance, no noise, vibration and balance.

A. Installation for ice machine:

1). Installing by the user: we will test and install the machine before shipment, all necessary spare parts, operation manual and CD are provided to guide the installation.

2).Installing by Icesnow engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user should provide accommodation and round-trip ticket for our engineer.

(2) Before our engineers’ arrival, the installation place, electricity, water and installation tools should be prepared. Meanwhile, we will provide you a Tool List with the machine when delivery.

(3) 1~ 2 workers are required to assist the installation for big project.

B. Warranty:

1) 24 months warranty after delivery.

2) Professional after-sales department to provide 24/7 technical support, all complaints should be replied within 24 hours.

3) Over 20 engineers available to service machinery overseas.

4) Free spare parts replacement within warranty period.

C. Why choose us ?

1) We have exported our ice machines to more than 150 countries;

2) Excellent Brand of China Ice Machine Industry;

3) The Drafting Committee of National Ice Machine Industrial Standard;

4) Produce & Academic Research Strategy Cooperating Partner with Tsing Hua University.

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for 2022 Good Quality Ice Making Flake Ice Drum - convenient installation Ice Flake Evaporator 20Ton/day – Icesnow , The product will supply to all over the world, such as: Poland, Montpellier, Brazil, we have complete material production line, assembling line , quality control system, and the most importantly, we have many patents technology and experienced technical&production team, professional sales service team. With all those advantages, we are going to create"the reputable international brand of nylon monofilaments", and spreading our products to every corner of the world. We are keep moving and try our best to serve our customers.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.