ICESNOW 500kg/day Flake Ice Machine for supermarket

Daily Capacity: 0.5-100 ton 24 hrs

Machine power supply: 3 phase industrial power supply

The control system is LG PLC, fully automated production, no manual operation.

The equipment can be used with stainless steel ice storage bins or polyurethane ice storage bins, and a wide range of accessories are available.

The flake ice machine is a device for direct low-temperature continuous ice making, and the ice temperature is as low as -8 ° C or lower, and the efficiency is high.

Flake ice is an irregular piece of ice, which is dry and clean, has a beautiful shape, is not easy to stick together, and has good fluidity.

The thickness of flake ice is generally 1mm-2mm, and it can be used directly without using a crusher.

| Name | Technical Data | Name | Technical Data |

| Ice production | 500kg/24h | Water pump Power | 0.014KW |

| Refrigeration capacity | 2801 Kcal | Brine Pump | 0.012KW |

| Evaporating temp. | -20℃ | Standard Power | 3P-380V-50Hz |

| Condensing Temp. | 40℃ | Inlet water pressure | 0.1Mpa-0.5Mpa |

| Ambient Temp. | 35℃ | Refrigerant | R404A |

| Inlet water Temp. | 20℃ | Flake ice Temp. | -5℃ |

| Total Power | 2.4kw | Feeding water tube size | 1/2" |

| Compressor Power | 3HP | Net weight | 190kg |

| Reducer Power | 0.18KW | Dimension (ice machine) | 1240mm×800mm×800mm |

| Model | Daily capacity | Refrigerant capacity | Total power (KW) | Ice machine size | Ice bin capacity | Ice bin size | Weight (kg) |

| (T/day) | (kcal/h) | (L*W*H/MM) | (kg) | (L*W*H/MM) | |||

| GM-03KA | 0.3 | 1676 | 1.6 | 1035*680*655 | 150 | 950*830*835 | 150 |

| GM-05KA | 0.5 | 2801 | 2.4 | 1240*800*800 | 300 | 1150*1196*935 | 190 |

| GM-10KA | 1 | 5603 | 4 | 1240*800*900 | 400 | 1150*1196*1185 | 205 |

| GM-15KA | 1.5 | 8405 | 6.2 | 1600*940*1000 | 500 | 1500*1336*1185 | 322 |

| GM-20KA | 2 | 11206 | 7.7 | 1600*1100*1055 | 600 | 1500*1421*1235 | 397 |

| GM-25KA | 2.5 | 14008 | 8.8 | 1500*1180*1400 | 600 | 1500*1421*1235 | 491 |

| GM-30KA | 3 | 16810 | 11.4 | 1648*1450*1400 | 1500 | 585 | |

| GM-50KA | 5 | 28017 | 18.5 | 2040*1650*1630 | 2500 | 1070 | |

| GM-100KA | 10 | 56034 | 38.2 | 3520*1920*1878 | 5000 | 1970 | |

| GM-150KA | 15 | 84501 | 49.2 | 4440*2174*1951 | 7500 | 2650 | |

| GM-200KA | 20 | 112068 | 60.9 | 4440*2174*2279 | 10000 | 3210 | |

| GM-250KA | 25 | 140086 | 75.7 | 4640*2175*2541 | 12500 | 4500 | |

| GM-300KA | 30 | 168103 | 97.8 | 5250*2800*2505 | 15000 | 5160 | |

| GM-400KA | 40 | 224137 | 124.3 | 5250*2800*2876 | 20000 | 5500 | |

| GM-500KA | 50 | 280172 | 147.4 | 5250*2800*2505 | 25000 | 6300 |

1. Long history: Icesnow has 20 years of ice machine production and R&D experience

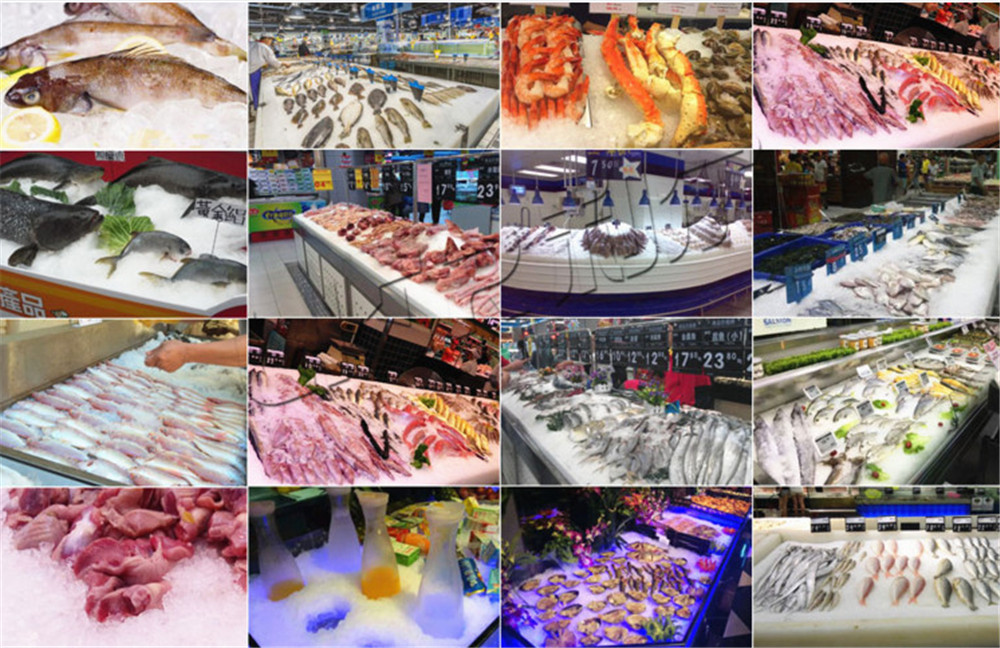

2. Flake Ice: Dry, pure, powder-less, not easy to block, its thickness is about 1.8mm~2.2mm, without edges or corners which will can product the cooling food, fish, seafood and other products.

3. Easy operation: Fully automatic operation using PLC programmable control system, stable performance, easy operation of ice maker, one key to start, no personnel to watch, ice out within one minute.

PLC control below:

1. Compressor high pressure protection

2. Compressor low pressure protection

3. Lack of water protection

4. Ice storage bin full of ice protection

5. Motor of speed reducer, water pump overload protection

6. High voltage protection

7. Low voltage protection

Pass the international CE, SGS, ISO9001 and other certification standards, the quality is reliable.

The ice machine parts are selected from Danish Danfoss, Copeland of America, Bitzer of Germany, Hanbell of Taiwan, Danfoss, and PLC controllers of international famous brands such as Korea PLC controller, with stable performance.

Evaporator

Drum: Use Stainless Steel material or Carbon Steel Chrominum. The scratch-style of inside machine ensures constant running at the lowest power consumption.

A. Installation for ice machine:

1. Installing by the user: we will test and install the machine before shipment, all necessary spare parts, operation manual and CD are provided to guide the installation.

2. Installing by Icesnow engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user should provide accommodation and round-trip ticket for our engineer.

(2) Before our engineers’ arrival, the installation place, electricity, water and installation tools should be prepared. Meanwhile, we will provide you a Tool List with the machine when delivery.

(3) 1~ 2 workers are required to assist the installation for big project.

B. Warranty:

1. 24 months warranty after delivery.

2. Professional after-sales department to provide 24/7 technical support, all complaints should be replied within 24 hours.

3. Over 20 engineers available to service machinery overseas.

4. Free spare parts replacement within warranty period