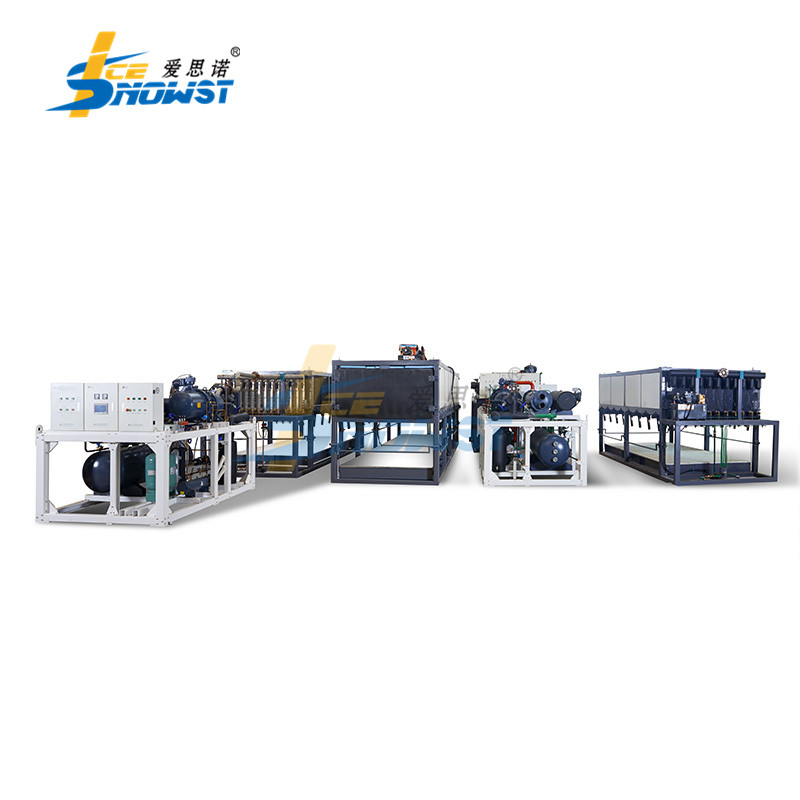

ICESNOW 60t/day Ice Block Machine for fishing cooling big capacity

Batch ice doffing process save 50% time compared with the traditional direct cooling ice machine, save time. Melting-resistant, higher ice output. Adopt ICESNOW rapid ice doffing technology shorten the time of ice block falling down, and the advanced measures of thermal insulation greatly save electricity.

With traditional ice doffing technology, fluorine gas circulate in the evaporator, which takes a long time to ice fall down. Block ice temperature will increase, block ice melt easily and more, so it consumes more electricity. However, with the application of ICESNOW rapid ice doffing technology, it greatly saves ice doffing time, and block ice temperature is lower, so it resistant to melting.

ICESNOW owns a skilled technical team can provide on-site installation and customize according to the block ice size, output capacity and machine configuration according to customer's requirement.

ICESNOW direct block ice machine has complete automatic control functions, not only including compressor high voltage protection, low voltage protection,oil shortage protection, phase sequence protection, compressor module protection,motor overload protection, but also including lifting platform limited protection, automatic watering, automatic ice doffing and other functions.

ICESNOW direct cooling block ice machine electrical control uses Schneider's PLC and touch screen, LS electrical components, etc., using Danfoss, Emerson, Faske valve, Bitzer compressor and other brand accessories.

| Comparison between direct cooling block ice machine & traditional brine refrigeration block ice machine | ||

| Power consumption | Direct cooling block ice machine | Brine system block ice machine |

| 50kWh/ton | 75kWh/ton | |

| Clean | Ice is sanitary, clean and edible. | Poor condition, mostly used for preservation and transportation |

| Way of ice doffing | Ice doffing by water or hot fluoride circulation, Short and fast ice freezing and doffing time. Labor cost saving. | Labor operation is needed, and ice freezing time is longer. |

| Area | Take a little area, convenient to transport, low construction cost. | Take larger area, higher construction cost. |

| Operation cost | Low | High |

| Working life | The material of ice moulds are Aluminum plate, mainframe adopts stainless steel, which is anti-rust and anti-corrosive. | The machine is be corroded and rusted by brine water. Service life is shorter. |

(1). Edible ice block machine the biggest features is that the large-scale ice blocks no need salty water and other cooling medium during the freezing period.

(2). When after the ice formed, it will dropping into the special ice contact convey device from the ice models, the whole course of ice forming is sanitary, clean, it can reach the edible request.

(3). The machine adopt the cycle heat has harvesting ice technology and direct heat expansion, heating exchange technology, making the product performance become more steady, it has broken the question of the large-scale can't for eat...

1. Integrated Cooling System

2. Specially designed evaporator

3. Ice clean and sanitary, meet the food standards

4. Refrigerant in line with national and international standards, can be used worldwide

5. Dry expansion evaporator reduce the use of refrigerant and installation failures, make the device compact and operation safe

6. Microcomputer full intelligent control. Water-supplying, Ice-making, Ice-falling Fault protection by self-fulfillment

7. Shortest time on construction site installation and commission, low the cost and risk of user’s

8. Mobile flexible, can be transported by truck and shi

9. Daily output: 1Ton~100Ton Each block ice weight: 20kg/25kg/30kg/50kg

10. High Container with ISO certificate

Installation:

1. Installing by the user: we will tested and install well the machine before shipment, all necessary spare parts, operation manual and CD are provided to guide the installation.

2.Installing by our engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user provide accommodation and round-trip ticket for our engineer.

(2) Before our engineer arrived in your site, the installation place, electricity, water and installation tools should be ready. Meanwhile, we will provide you a Tool List with the machine when delivery.

(3) All spare parts are provided according to our standard. During installation period, any shortage of parts due to the actual installation site, the buyer is required to afford the cost, such as water pipes.

(4) 2~ 3 workers are required to assist the installation for big project.

1. Q: are you add refrigerant in the ice machine?

A: yes, the machine is full of refrigerant, once with water and electric it can work. yes, ice machine leaves factory with carefully examination after it was produced for 3 to 5 days. And when we install them at customer’s factory, we retest the ice machines.

2. Q:do you test the ice machine in your factory?

A: yes, ice machine leaves factory with carefully examination after it was produced for 3 to 5 days. And when we install them at customer’s factory, we retest the ice machines.

3. Q: can you load ice machine into container?

A: we have containerized ice block machine. Our export ice machine is designed based on the standard of container, it is easily to load. The 25kg ice of 10tons can load in container of 40 feet.

for domestic ice machine of over 12 tons per day, we design based on the standard of truck, which can easily drive into your factory.

4. Q: all your ice machine is based on 380V 50HZ power requirement? Do you have the right power requirement for abord? Such as 440V 60HZ or 220V three phase that suitable for America?

A: our ice machine and power,voltage can suitable for your country, please make the power requirement be clear in your order.