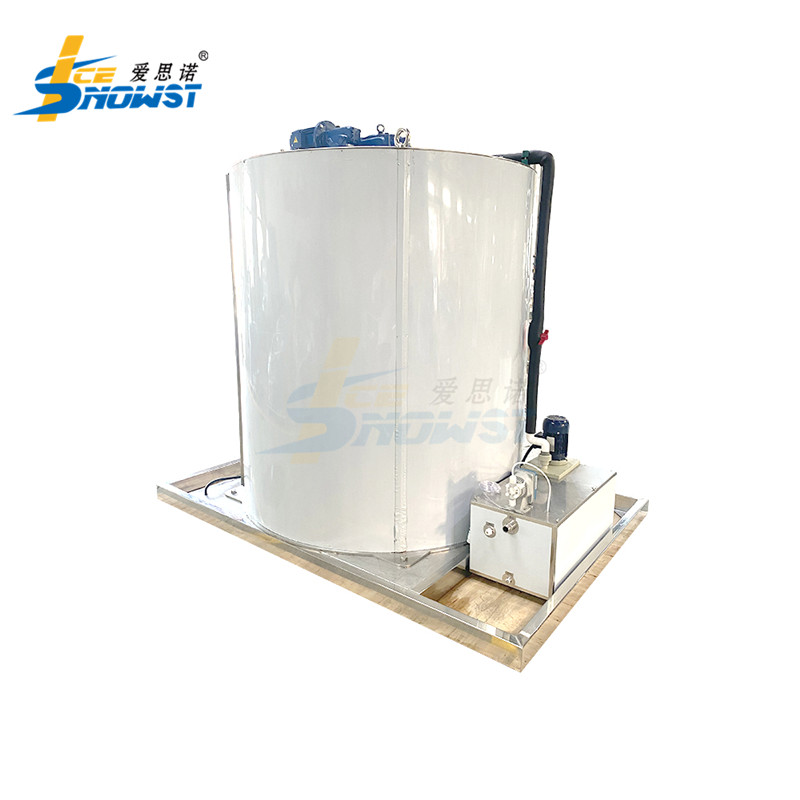

Discount Price Large Cube Ice Machine - Stainless Steel Flake Ice Machine Commercial Ice Flaker Machine For Bread Processing 500kg/Day – Icesnow

Discount Price Large Cube Ice Machine - Stainless Steel Flake Ice Machine Commercial Ice Flaker Machine For Bread Processing 500kg/Day – Icesnow Detail:

1. Daily Capacity: 500kg/24 hrs

2. Machine power supply: 3P/380V/50HZ,3P/380V/60HZ,3P/440V/60HZ

3.The equipment can be used with stainless steel ice storage bins or polyurethane ice storage bins, and a wide range of accessories are available.

4. Flake ice is an irregular piece of ice, which is dry and clean, has a beautiful shape, is not easy to stick together, and has good fluidity.

5.The thickness of flake ice is generally 1.1mm-2.2mm, and it can be used directly without using a crusher.

6. All Material are stainless steel

1 .flake ice Evaporator Drum: Use Stainless Steel material or Carbon Steel Chrominum. The scratch-style of inside machine ensures constant running at the lowest power consumption.

2.Thermal insulation: foaming machine filling with imported polyurethane foam insulation. Better effect.

3. Pass the international CE, SGS, ISO9001 and other certification standards, the quality is reliable.

4.Ice blade: made of SUS304 material seamless steel tube and formed through only one time process. It’s durable.

|

Technical Data |

|

|

Model |

GM-05KA |

|

Ice production |

500kg/24h |

|

Refrigeration capacity |

3.5KW |

|

Evaporating temp. |

-25℃ |

|

Condensing Temp. |

40℃ |

|

Power supply |

3P/380V/50HZ |

|

Total Power |

2.4KW |

|

Cooling mode |

Air cooling |

|

Ice bin capacity |

300kg |

|

Dimension of flake ice machine |

1241*800*80mm |

|

Dimension of ice bin |

1150*1196*935mm |

1. Long history: Icesnow has 20 years of ice machine production and R&D experience

2. Easy operation: Fully automatic operation using PLC programmable control system, stable performance, easy operation of ice maker, one key to start, no person need monitor the ice machine

3. Higher refrigeration efficiency and lower loss of refrigeration capacity.

4. Simple structure and small land area .

5. High quality , dry and no-caked. The thickness of flake ice which produced by automatic ice flake making machine with vertical evaporator is about 1 mm to 2 mm. The ice shape is irregular flake ice and it has good mobility.

A. Installation for ice machine:

1). Installing by the user: we will test and install the machine before shipment, all necessary spare parts, operation manual and CD are provided to guide the installation.

2).Installing by Icesnow engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user should provide accommodation and round-trip ticket for our engineer.

(2) Before our engineers’ arrival, the installation place, electricity, water and installation tools should be prepared. Meanwhile, we will provide you a Tool List with the machine when delivery.

(3) 1~ 2 workers are required to assist the installation for big project.

Product detail pictures:

Related Product Guide:

We goal to see good quality disfigurement within the manufacturing and provide the most effective support to domestic and overseas shoppers wholeheartedly for Discount Price Large Cube Ice Machine - Stainless Steel Flake Ice Machine Commercial Ice Flaker Machine For Bread Processing 500kg/Day – Icesnow , The product will supply to all over the world, such as: Barcelona, Turkey, New Zealand, With a team of experienced and knowledgeable personnel, our market covers South America, the USA, the Mid East, and North Africa. Many customers have become our friends after good cooperation with us. If you have the requirement for any of our products, please contact us now. We are looking forward to hearing from you soon.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!