Fast delivery Containerized Ice Block Making Machine - energy-saving tube ice machine 2T – Icesnow

Fast delivery Containerized Ice Block Making Machine - energy-saving tube ice machine 2T – Icesnow Detail:

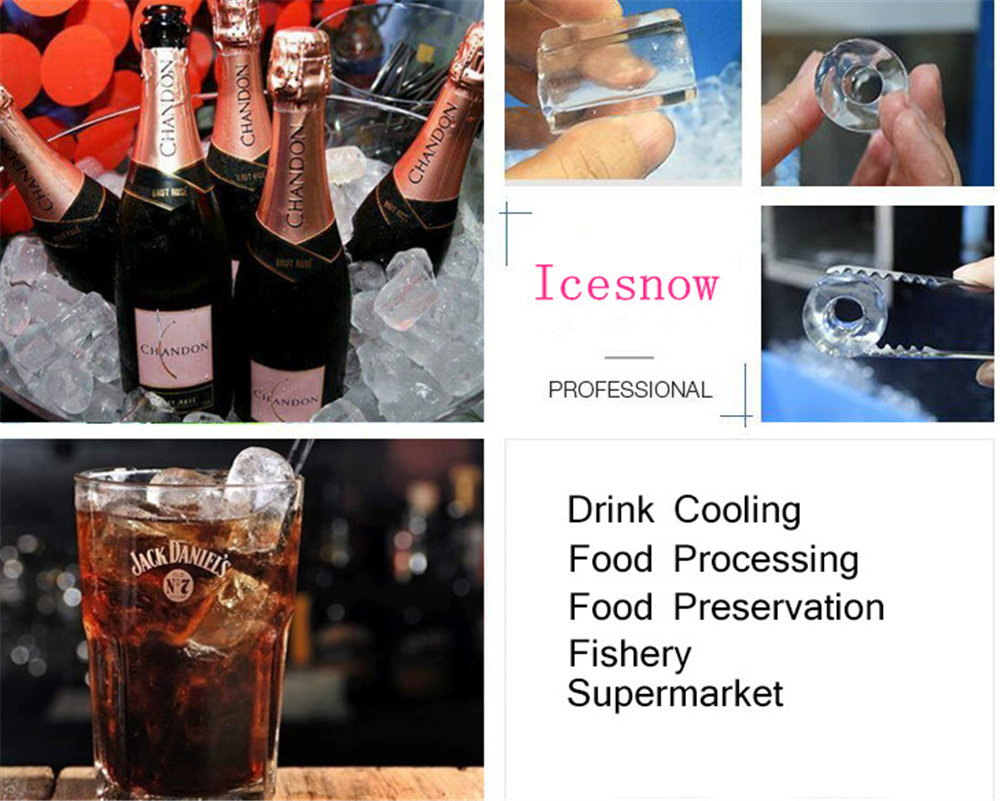

With high density, ice purity and not easy to melt, especially tube ice is very beautiful. Tube ice is popular in catering&beverage and food fresh keeping. The ice is very common in our daily life and commercial using.

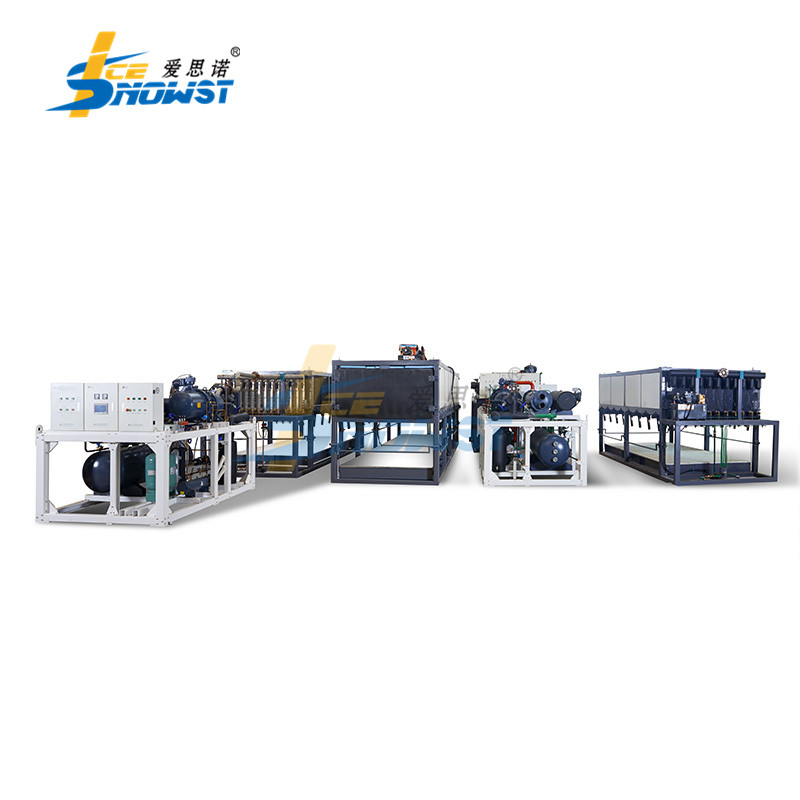

1. Integrated modular design, easy to maintain and transport.

2. Advanced water circulation systems, ensure the ice quality: purify and transparent.

3. Fully-automatic production system, and labor saving, efficient.

4. Two ways heat-exchange system, high efficiency, simple&safe operating.

5. Self-design, self-production, optimize every processing works, make the machine a perfect performance.

6. All the components are adopted from professional suppliers, result in excellent efficiency and stable running.

| Product Name | Tube Ice Machine |

| Output | 2ton/24hours |

| Model | ISN-TB20 |

| Total Power | 12 kw |

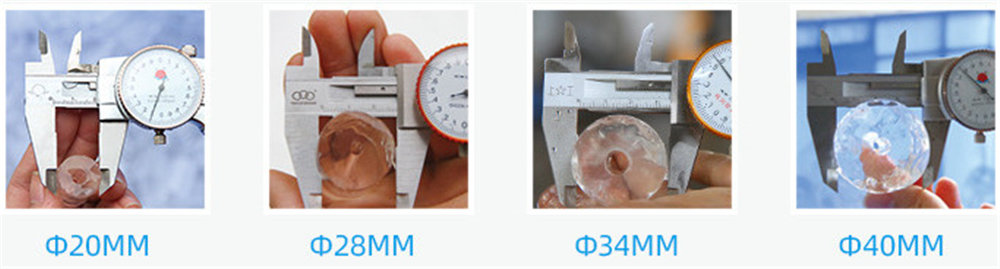

| Ice diameter | 22mm,28mm or 35mm for option |

| Machine material | SS304 stainless steel tube |

| Machine size | about 1650*1250*2250 (mm) |

| Machine weight | about 1350kgs |

| Tube ice feature | Tube ice has high density. Tube ice is hard, powderless, clean, pure, glittering, hollow shaped, not easy to melt.The ice is very common in our daily life and commercial using. |

| Application of tube ice | Drinks, Catering & Beverage, Hotels, Food processing, Vegetable & fruit fresh keeping, Temp control of Industry and Industrial Production etc. |

A. The working status of the ice system display alive in screen

B. Setting stop-time at will.

C. All possible failure and trouble-shooting is programmed in.

D. Local time could be setting

E. The ice thickness could be adjusted with setting the icing time by finger.

F. Different languages version

The company has a construction team with extensive overseas installation experience, and they have bulit more than 50 large-scale projects worldwide.

The company has a construction team with extensive overseas installation experience, and they have bulit more than 50 large-scale projects worldwide.

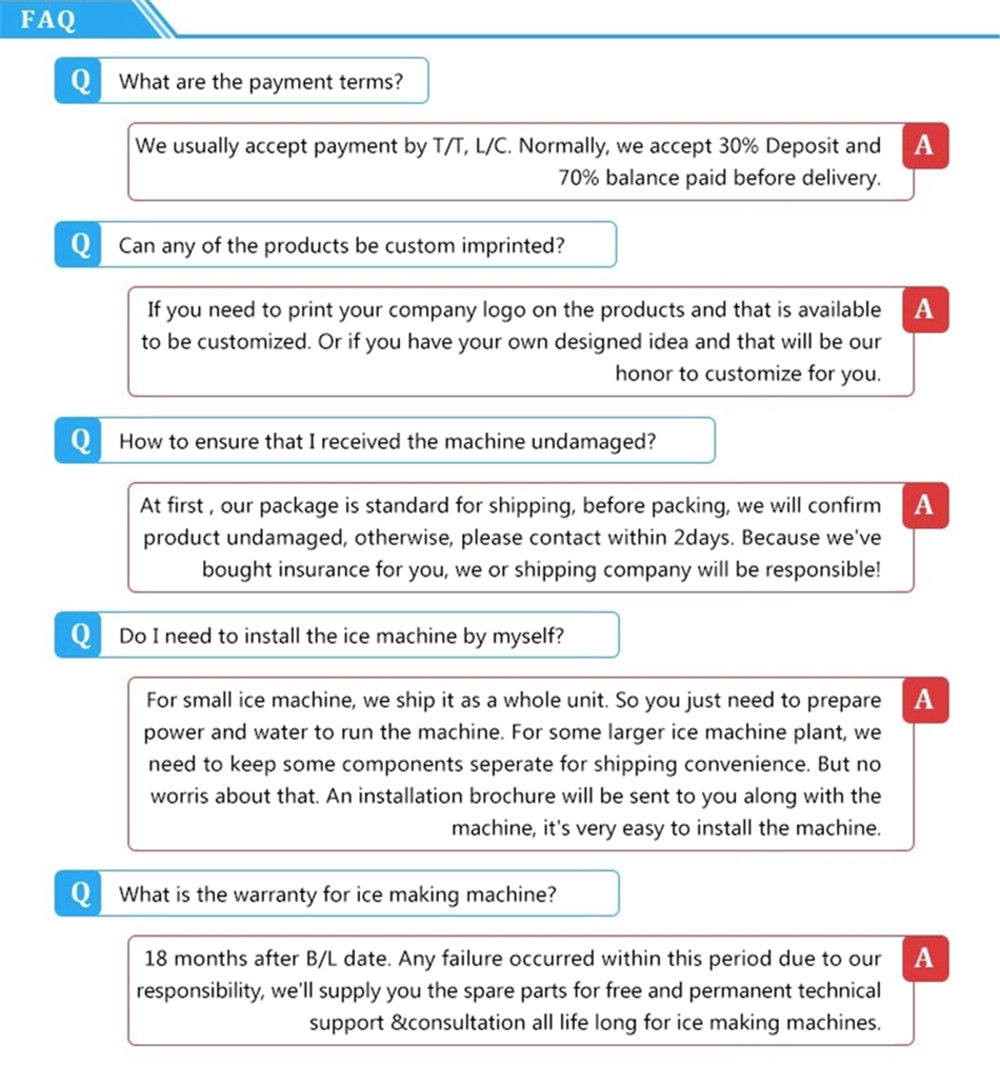

Installation:

1. Installing by the user: we will tested and install well the machine before shipment, all necessary spare parts, operation manual and CD are provided to guide the installation.

2. Installing by our engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user provides accommodation and round-trip ticket for our engineer.

(2) Before our engineer arrived in your site, the installation place, electricity, water and installation tools should be ready. Meanwhile, we will provide you a Tool List with the machine when delivery.

(3) All spare parts are provided according to our standard. During installation period, any shortage of parts due to the actual installation site, the buyer is required to afford the cost, such as water pipes.

(4) 1~ 2 workers are required to assist the installation for big project.

Product detail pictures:

Related Product Guide:

Gaining purchaser gratification is our firm's intention eternally. We will make wonderful endeavours to build new and top-quality merchandise, satisfy your exclusive needs and provide you with pre-sale, on-sale and after-sale products and services for Fast delivery Containerized Ice Block Making Machine - energy-saving tube ice machine 2T – Icesnow , The product will supply to all over the world, such as: Singapore, Manila, Cape Town, Our staffs are rich in experience and trained strictly, with professional knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to provide the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we will develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.