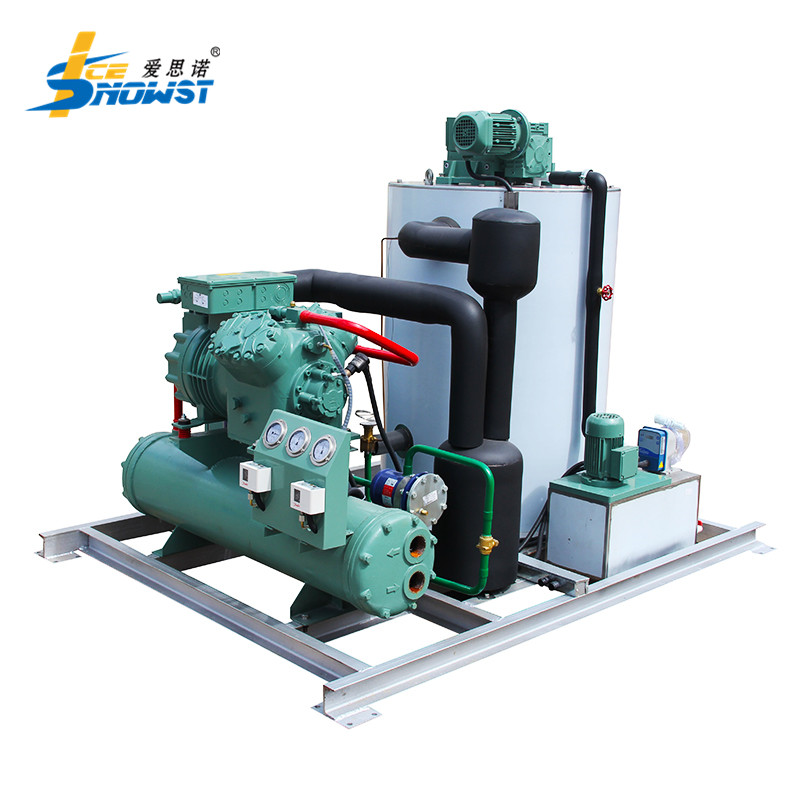

ICESNOW 5T/day Flake Ice Plant for water cooling fast working

● Daily Capacity: 5 ton 24 hrs

● Machine power supply: 3P/380V/50HZ,3P/220V/60HZ,3P/380V/60HZ,

● PLC intelligent control system, fully automated production, no manual operation required

● Adopt environmentally friendly refrigerant, environmental protection, high efficiency and energy saving

● The overall modular equipment is very easy to transport, move and install on site

● Direct low temperature continuous ice formation, ice temperature below -8 °C, high efficiency

● The whole machine has passed CE certification and has high security

● The ice maker designed and manufactured according to the pressure vessel standard is sturdy, safe and reliable

● Flake Ice shape with excellent cooling performance

● No sharp edges, so it no hurt the cooling products

● 1~2 mm thickness, no need to crush and can use at any time

1. Refrigerating unit -- Main parts of refrigerating units are all from America, Germany, Japan and other countries that have leading refrigeration technology.

2. PLC programmable control system -- The machine can start and stop automatically to make the evaporator mechanical operation system and water supplying circulation system coordination matched and work safely & efficiently under the control of PLC controller. The whole system is protected by the alarm of water shortage, ice full, high and low pressure abnormal, power phase inverse and compressor overload, etc.with the computer intelligence control.

When there is a failure, the PLC will stop the unit automatically and the corresponding alarming indicator lights up. And when the fault is settled, PLC controller will soon start the machine after receiving the information. The whole system is controlled automatically well without hand operation.

3. Evaporator--Ice machine evaporator adopts the fixed static vertical design, namely the evaporator is static and the ice blade rotate in the inner wall to scrape ice. The design reduces the wear, has high sealing and avoids the leakage of the refrigerant effectively. It is made of SUS 304 material and adopts automatic fluorine welding technology to improve its intensity and accuracy.

4. Ice blade--Spiral ice blade, small resistance, low loss, no noise and making ice in uniform.

| Model | Daily capacity | Refrigerant capacity | Total power (KW) | Ice machine size | Ice bin capacity | Ice bin size | Weight (kg) |

| (T/day) | (kcal/h) | (L*W*H/MM) | (kg) | (L*W*H/MM) | |||

| GM-03KA | 0.3 | 1676 | 1.6 | 1035*680*655 | 150 | 950*830*835 | 150 |

| GM-05KA | 0.5 | 2801 | 2.4 | 1240*800*800 | 300 | 1150*1196*935 | 190 |

| GM-10KA | 1 | 5603 | 4 | 1240*800*900 | 400 | 1150*1196*1185 | 205 |

| GM-15KA | 1.5 | 8405 | 6.2 | 1600*940*1000 | 500 | 1500*1336*1185 | 322 |

| GM-20KA | 2 | 11206 | 7.7 | 1600*1100*1055 | 600 | 1500*1421*1235 | 397 |

| GM-25KA | 2.5 | 14008 | 8.8 | 1500*1180*1400 | 600 | 1500*1421*1235 | 491 |

| GM-30KA | 3 | 16810 | 11.4 | 1648*1450*1400 | 1500 | 585 | |

| GM-50KA | 5 | 28017 | 18.5 | 2040*1650*1630 | 2500 | 1070 | |

| GM-100KA | 10 | 56034 | 38.2 | 3520*1920*1878 | 5000 | 1970 | |

| GM-150KA | 15 | 84501 | 49.2 | 4440*2174*1951 | 7500 | 2650 | |

| GM-200KA | 20 | 112068 | 60.9 | 4440*2174*2279 | 10000 | 3210 | |

| GM-250KA | 25 | 140086 | 75.7 | 4640*2175*2541 | 12500 | 4500 | |

| GM-300KA | 30 | 168103 | 97.8 | 5250*2800*2505 | 15000 | 5160 | |

| GM-400KA | 40 | 224137 | 124.3 | 5250*2800*2876 | 20000 | 5500 | |

| GM-500KA | 50 | 280172 | 147.4 | 5250*2800*2505 | 25000 | 6300 |

Stainless steel ice making platform

Danfoss Expansion valve

1. As Its flat and thin shape, It has got the largest contact area among all types of ice. The larger its contact area Is, the faster it cools other stuff.

2. Perfect in food cooling: Flake ice Is type of dry and crispy Ice, it hardly forms any shape edges. In food cooling process, this nature has made It the best material for cooling, it can reduce the possibility of damage to food to the lowest rate.

3. Thoroughly mixing: Flake Ice can become water quickly through the rapid heat exchanging with products, and also supply the moisture for products to be cooled.

4. Flake ice low temperature: -5℃~-8℃:Flake ice thickness: 1.8-2.5 mm, can be used directly for food fresh without ice crusher any more, saving cost.

5. Fast ice making speed: Can produce ice within 3 minutes after starting It, do not need extra person to take off and get the ice.

A. Installation for ice machine:

1. Installing by the user: we will test and install the machine before shipment, all necessary spare parts, operation manual and CD are provided to guide the installation.

2. Installing by Icesnow engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user should provide accommodation and round-trip ticket for our engineer.

(2) Before our engineers’ arrival, the installation place, electricity, water and installation tools should be prepared. Meanwhile, we will provide you a Tool List with the machine when delivery.

(3) 1~ 2 workers are required to assist the installation for big project.