Good Quality Flake Ice Machine - CE Certificate 2.5ton/day ice flake making machine – Icesnow

Good Quality Flake Ice Machine - CE Certificate 2.5ton/day ice flake making machine – Icesnow Detail:

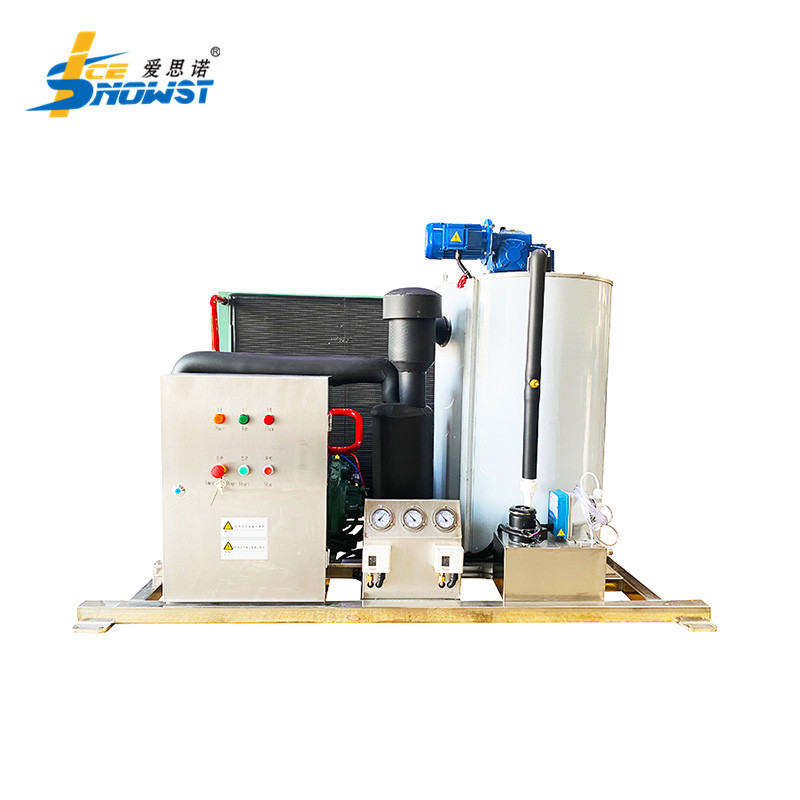

Three different condenser alternatives are offered:

Air cooled condenser

Water cooled condenser

Evaporative condenser

Before leaving our factory every unit is tested to meet specification parameters.

Units from 0.5 - 2.5 tons come with Famous brands danfoss compressors.

Units from 3 – 12 tons come with Bitzer compressors

Units from 15 – 50 tons come with Hanbell compressors

| Name | Technical Parameters |

| Model | GM-25KA |

| ice production (days) | 2500kg/day |

| Unit weight (kg) | 491Kg |

| Unit dimension (mm) | 1500mm×1180mm×1055mm |

| Dimension of ice bin (mm) | 1500mm×1676mm×1235mm |

| Ice bin capacity | 600kg |

| Thickness of ice flake (mm) | 1.5mm-2.2mm |

| Refrigerant | R404A |

| Installed total power | 8.8KW |

| Compressor | Danfoss |

| Compressor horse power | 12HP |

| Flake ice temperature | -5–8℃ |

| cooling method | Air cooling |

1. Supermarket preservation: Keep the food and vegetable fresh and beautiful.

2. Fishery industry: Keeping Fish fresh during sorting, shipping and retailing,

3. Slaughtering industry: Maintain temperature and keep the meat fresh.

4. Concrete construction: Reduce the temperature of concrete during mixing, making the concrete more easy to composite.

1. Safe operation and good reliability

All accessories and parts of Icesnow system are adopted of top-level products of western or local markets, greatly enhance the products quality.

2. Easy operation

The cooling system and flake ice evaporator is automatically controlled by micro-computer, and has protection for phase lack, reverse, H/low pressure and bin full which makes the operation more reliable and steady, reduced the possibility of damage, easy for maintenance.

3. The ice Skates is a screw scraper, features low resistance, low consumption, no noise.

(1) Be made of low-temperature pressure vessel special materials and passed precision processing;

(2 )More sufficient evaporation area and better performance with dry style evaporation way;

(3) Whole processing is made by vertical lathe to ensure the precision up to 2 ounces;

(4) Be designed and produced with standard low-temperature pressure vessel manufacturing process, including surface treatment, heat treatment, gas-tight test, tensile & compression strength test, etc.

(5) Using imported refrigeration accessories;

(6) All water supply line are made of stainless steel, high sanitary condition;

(7) Fast ice forming & falling speed, ice begins within 1 to 2 minutes.

(8) Ice blade: made of SUS304 material seamless steel tube and formed through only one time process. It’s durable.

(9) Spindle and other accessories: made of SUS304 material through precision machining, and conform to food hygiene standards.

(10) Thermal insulation: foaming machine filling with imported polyurethane foam insulation. Better effect.

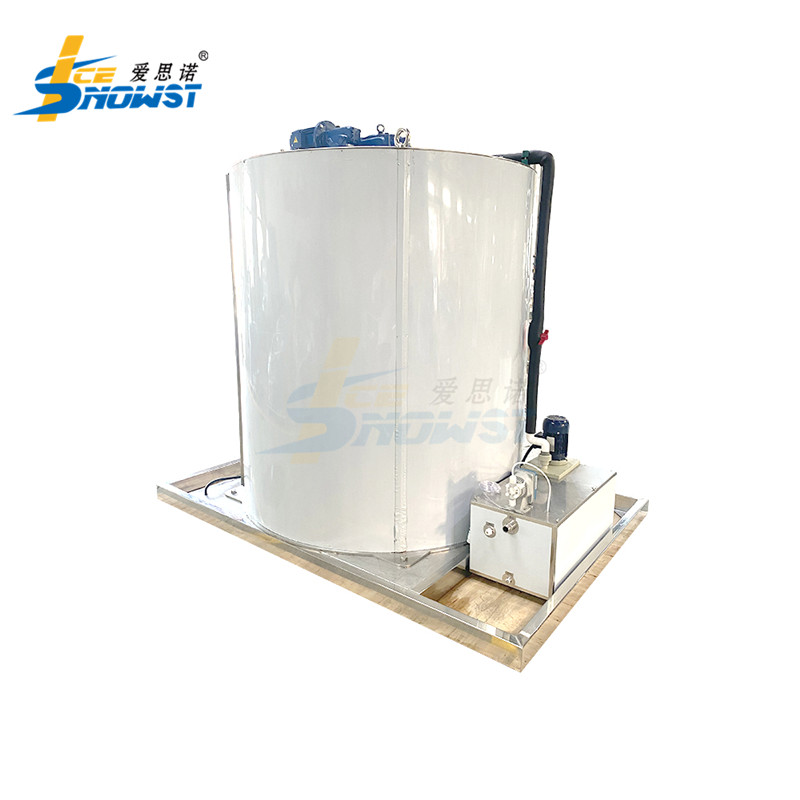

Product detail pictures:

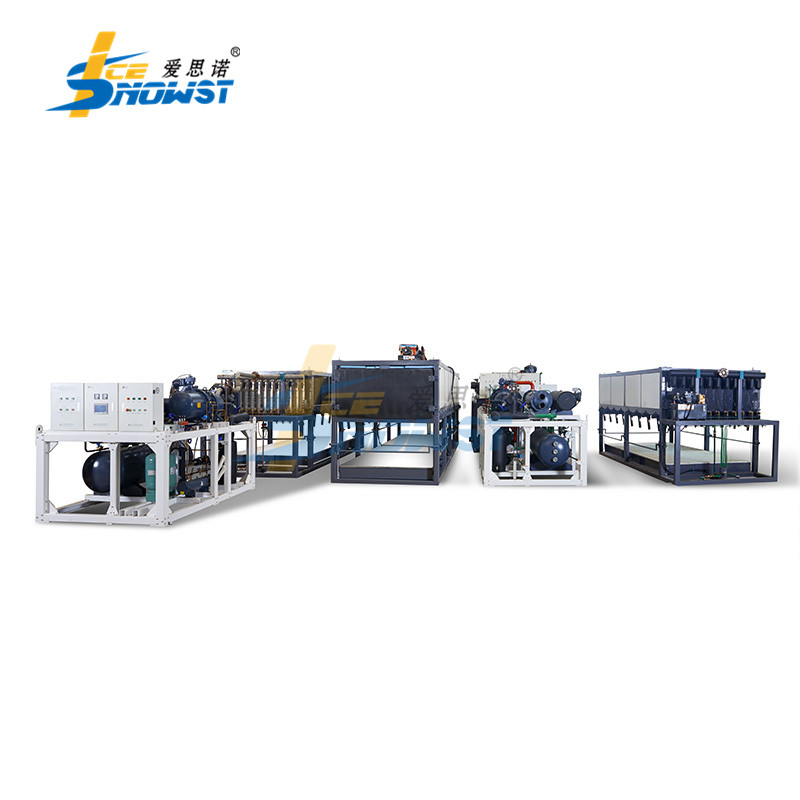

Related Product Guide:

Our business has been focusing on brand strategy. Customers' pleasure is our best advertising. We also offer OEM company for Good Quality Flake Ice Machine - CE Certificate 2.5ton/day ice flake making machine – Icesnow , The product will supply to all over the world, such as: Singapore, Uruguay, Tanzania, Welcome to visit our company and factory, there are various products displayed in our showroom that will meet your expectation, meanwhile, if you are convenient to visit our website, our sales staff will try their efforts to provide you the best service

Sales manager is very enthusiastic and professional, gave us a great concessions and product quality is very good,thank you very much!