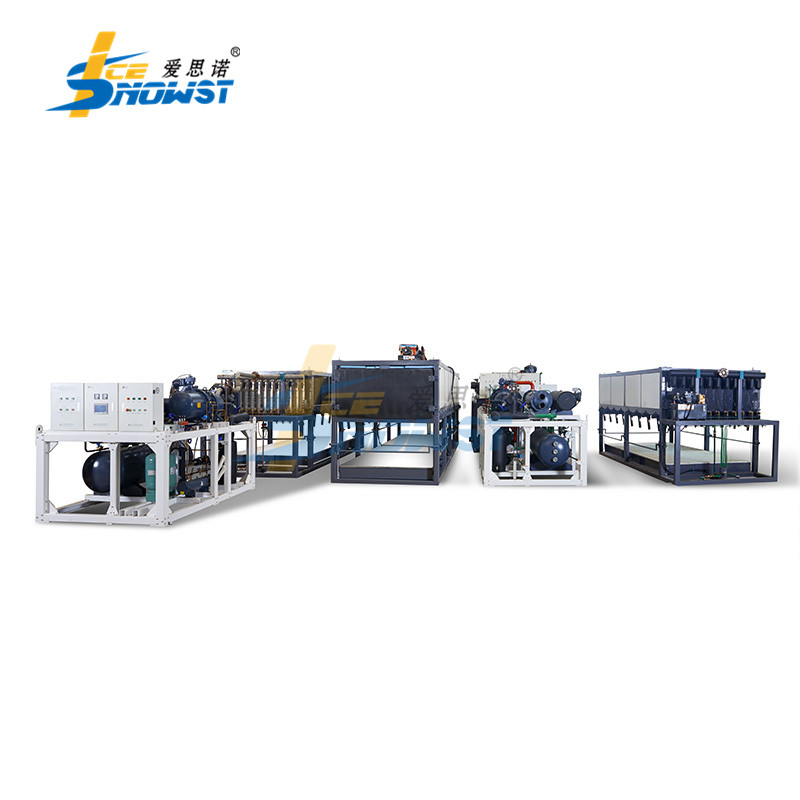

Good Quality Tube Ice Machine - High Efficiency Automatic 5T/day ice tube machine with remote air cooled condenser – Icesnow

Good Quality Tube Ice Machine - High Efficiency Automatic 5T/day ice tube machine with remote air cooled condenser – Icesnow Detail:

| Item | Name of Components | Brand Name | Original Country |

| 1 | Compressor | BITZER | Germany |

| 2 | Ice Maker Evaporator | ICESNOW | China |

| 3 | air cooled condenser | ICESNOW | |

| 4 | Refrigeration components | DANFOSS/CASTAL | Denmark/Italy |

| 5 | PLC Program control | SIEMENS | Germany |

| 6 | Electrical components | LG (LS) | South Korea |

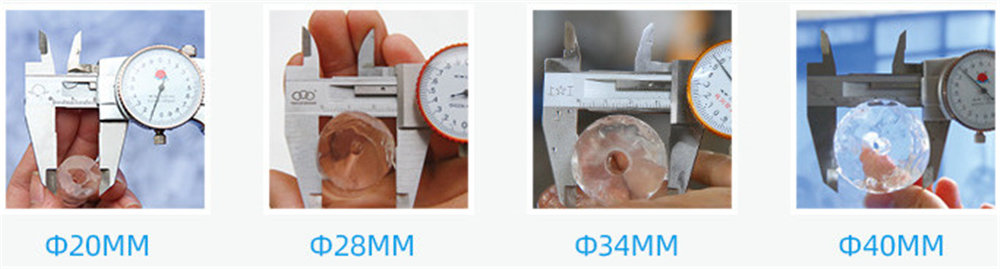

With high density, ice purity and not easy to melt, especially tube ice is very beautiful. Tube ice is popular in catering&beverage and food fresh keeping. The ice is very common in our daily life and commercial using.

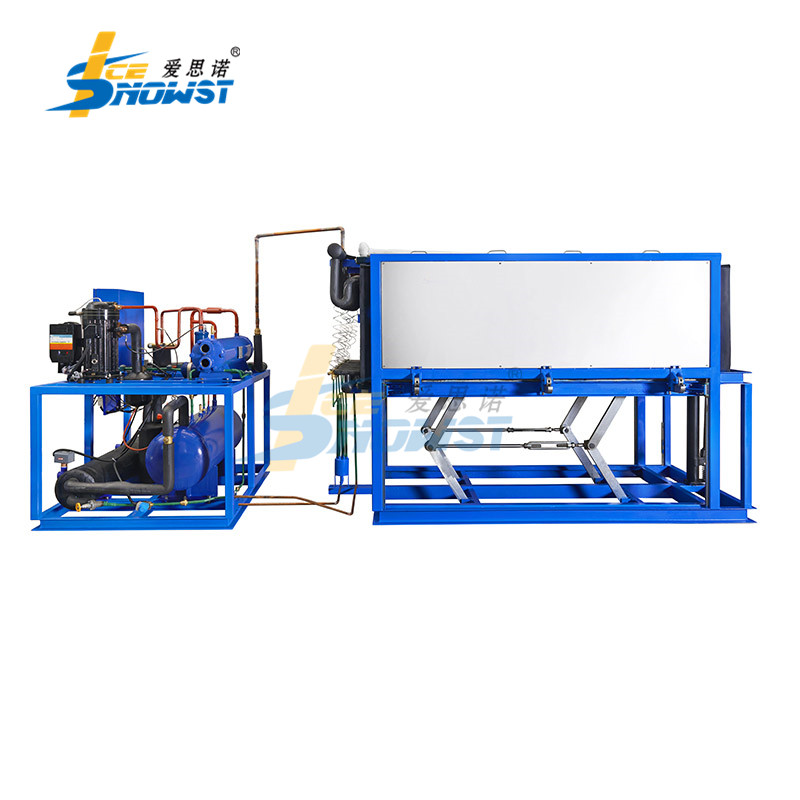

1. Integrated modular design, easy to maintain and transport.

2. Advanced water circulation systems, ensure the ice quality: purify and transparent.

3. Fully-automatic production system, and labor saving, efficient.

4. Two ways heat-exchange system, high efficiency, simple&safe operating.

5. Self-design, self-production, optimize every processing works, make the machine a perfect performance.

6. All the components are adopted from professional suppliers, result in excellent efficiency and stable running.

| Name | Technical Data | Name | Technical Data |

| Ice production | 5ton/day | Cooling mode | Air cooled |

| Refrigeration capacity | 35KW | Standard Power | 3P-380V-50Hz |

| Evaporating temp. | -15℃ | Ice tube diameter | Φ22mm/28mm/35mm |

| Condensing Temp. | 40℃ | Ice length | 30 ~ 45MM |

| Total Power | 25.2kw | tube ice weight density | 500~550kg/m3 |

| Compressor Power | 22KW | Evaporator type | Stainless steel seamless steel pipe |

| Ice cutter Power | 0.75KW | Ice tube material | SUS304 stainless steel |

| Water pump Power | 0.75KW | Water tank material | SUS304 stainless steel |

| Air cooled power | 1.65KW | Ice cutting blade material | SUS304 stainless steel |

| Net weight | 3210kg | Dimension of tube ice machine | 1900*1000*2080mm |

| Refrigerant | R404A/R22 | Dimension of air cooled condenser | 2646*1175*1260mm |

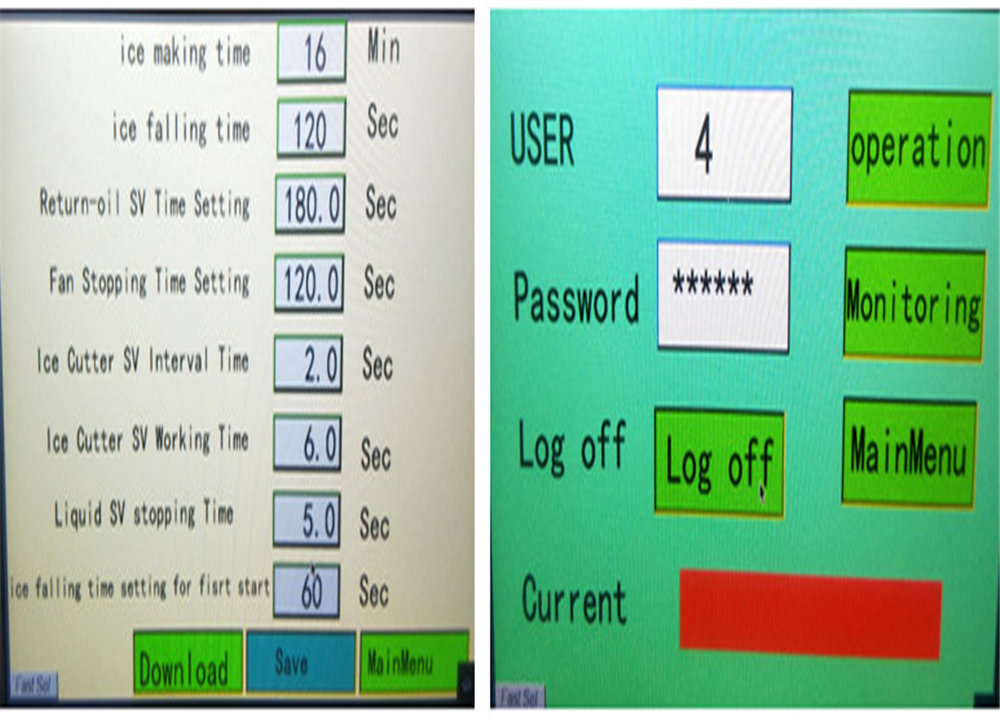

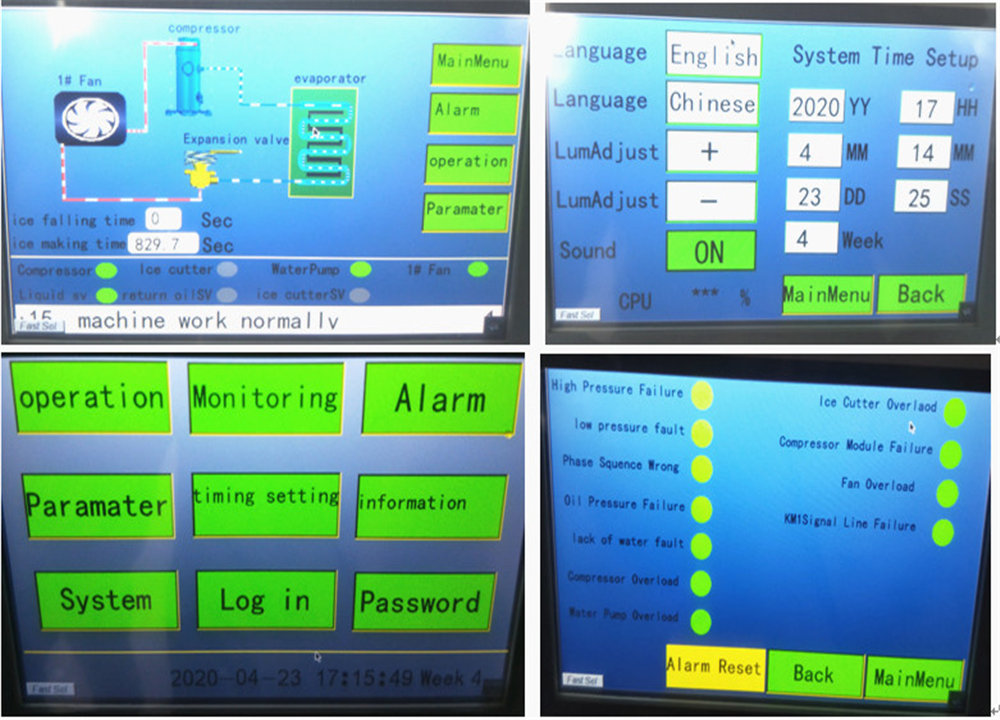

A. The working status of the ice system display alive in screen

B. Setting stop-time at will.

C. All possible failure and trouble-shooting is programmed in.

D. Local time could be setting

E. The ice thickness could be adjusted with setting the icing time by finger.

F. Different languages version

1. High reliability and low fault failure

80% components of the tube ice maker system are world famous brand.Through decades of research and practice,it can run continuously without fault and keep good run and stable ice output even in ambient temperature 5°C-40°C.Special designed machine can even allow normal run in the most atrocious conditions(-5°C-+56°C)

2. Scientific design and advanced processing technique

Scientific design and can also make the best ice making system according to customers actual demand, with world leading ice making technology and processing and testing equipments .Each part is processed with strict technique requirement and strictly tested before using.

3. Sanitary

Quality and sanitary tube ice maker .All parts contacting with water are made of stainless steel SUS304 or SUS316L and PE material .

4. With stable continuous running ,the tube ice maker realizes the running without energy wasting.Compared with orher ice making equipments,the ice maker boasts the advantages of compact structure,small area,low production cost,high refrigeration effect and low energy consumption.

5. Module design and simple maintenance

The ice maker has module design for simple maintenance on site. Tube ice maker can be installed inside a standard container, very suitable for frequent moving occasion.

6. PLC are adopted for tube ice maker to realize one-key operation.Several sets of large system in parallel connection can be centrally controlled with remote control interface.

The company has a construction team with extensive overseas installation experience, and they have bulit more than 50 large-scale projects worldwide.

1. Installing by the user: we will tested and install well the machine before shipment, all necessary spare parts, operation manual and CD are provided to guide the installation.

2. Installing by our engineers:

(1) We can send our engineer to assist the installation and provide technical support and train your workers. The end-user provides accommodation and round-trip ticket for our engineer.

(2) Before our engineer arrived in your site, the installation place, electricity, water and installation tools should be ready. Meanwhile, we will provide you a Tool List with the machine when delivery.

(3) All spare parts are provided according to our standard. During installation period, any shortage of parts due to the actual installation site, the buyer is required to afford the cost, such as water pipes.

(4) 1~ 2 workers are required to assist the installation for big project.

Product detail pictures:

Related Product Guide:

Our team through qualified training. Skilled professional knowledge, powerful sense of support, to satisfy the support desires of consumers for Good Quality Tube Ice Machine - High Efficiency Automatic 5T/day ice tube machine with remote air cooled condenser – Icesnow , The product will supply to all over the world, such as: venezuela, Swedish, Switzerland, "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, You should contact with us now!

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!