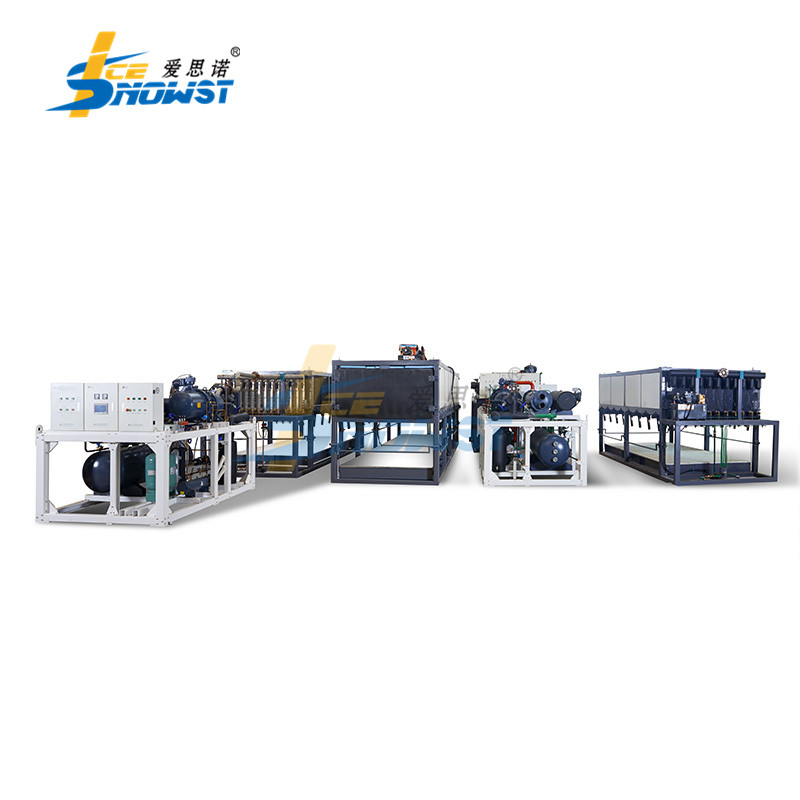

High reputation Cube Ice Maker - Full Automatic 20T/day tube ice maker – Icesnow

High reputation Cube Ice Maker - Full Automatic 20T/day tube ice maker – Icesnow Detail:

| Pure Ice | Using Pre-PurifyTM water purification technology to filter the incoming water, the ice tube are crystal clear. |

| Perfect Design | All the equipment adopts CAD-3D simulation assembly, which makes the arrangement of equipment parts and accessories and the direction of pipes more reasonable, compact structure and not crowded, and more humanized operation and maintenance. |

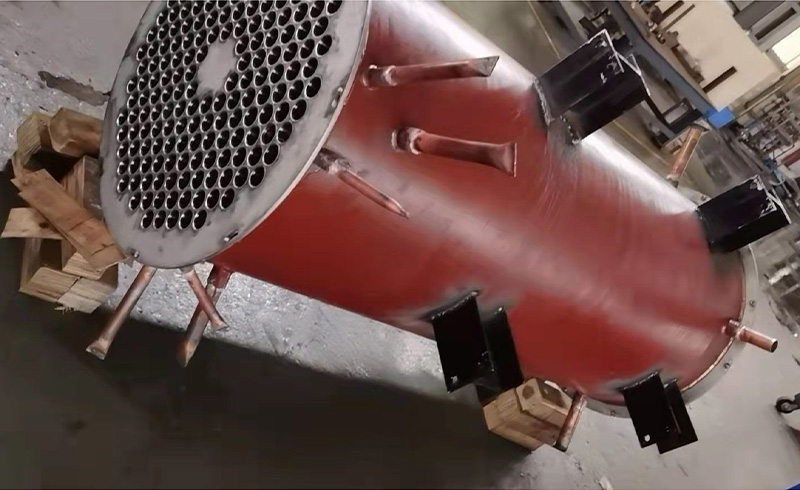

| Safety and Hygiene | Evaporator materials are made of stainless steel 304 and other materials, reaching the international health standards. |

| Efficient Performance | The evaporator adopts special processing technology, which makes the evaporator have better thermal conductivity. |

| Energy Saving And Water Saving | Each compressor condensing unit is equipped with heat exchange of return pipe and liquid supply pipe, control of evaporation temperature and condensation temperature, superheat of return gas and oil return, so as to ensure stable operation of compressor unit under safe working conditions. |

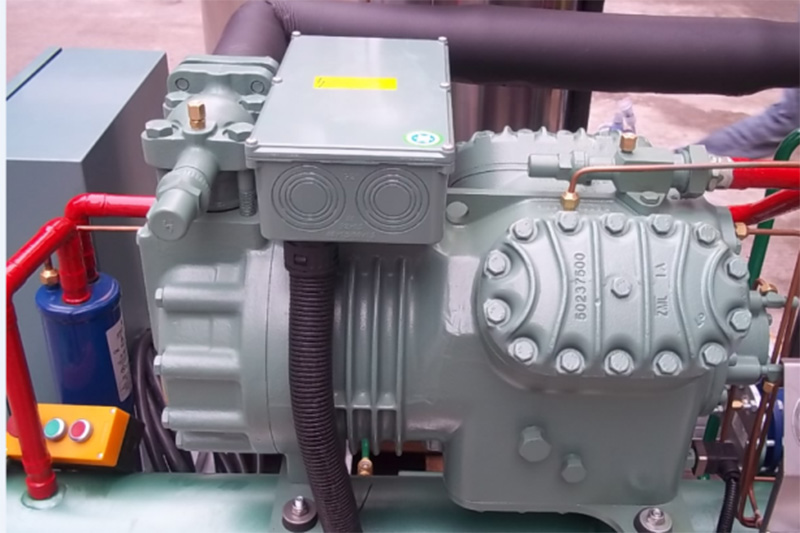

| High Quality Accessories | More than 80% of the refrigeration equipment accessories produced by Icesnow use well known brands at home and abroad. For example, Bitzer is used for the compressor. Hansen, Danfoss, Emerson and other world famous brands are used as refrigeration accessories. |

| Customized | The refrigeration equipment produced by Icesnow can operate normally under the working conditions of -20~+50℃ and water inlet temperature of +0.5~+45℃. The company can not only provide all kinds of standard refrigeration equipment for you but also customized the refrigeration system under special working conditions according to the actual needs. |

| Stable and Reliable | Perfect design, reduce the equipment internal unnecessary transmission parts, so that the equipment more simple and reliable. The unit is generally equipped with low water level, water flow, full ice, high pressure compressor, low pressure of compressor, oil pressure of compressor, et., so that the equipment can operate stably, reliably, and safely, and can operate continuously for more than 3000 hours without fault. |

| Standardization | Most of the products have been standardized, so that the production quality and processing technology are more mature and the quality is more guaranteed. |

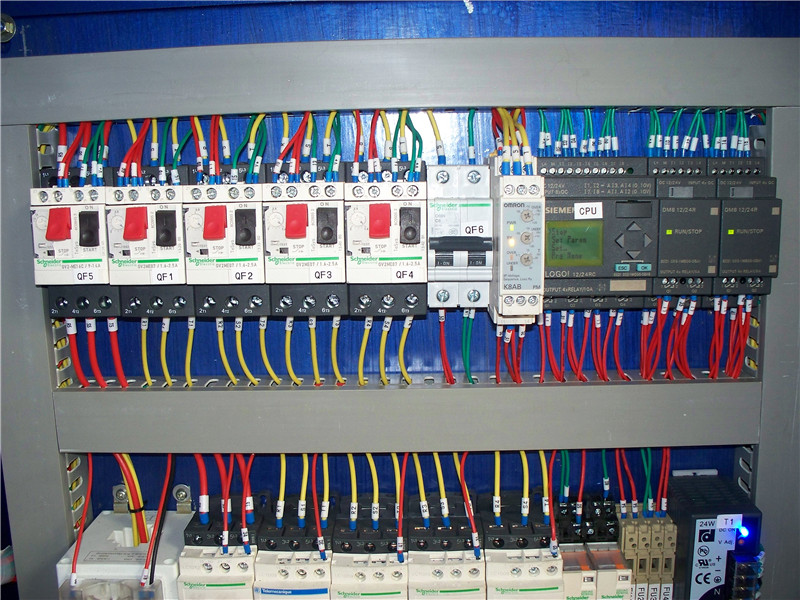

| Fully Automatic | PLC computer module automatically controls ice making process at a glance. |

| Name | Technical Data | Name | Technical Data |

| Ice production | 20ton/day | Cooling mode | water cooled |

| Refrigeration capacity | 170KW | Standard Power | 3P-380V-50Hz |

| Evaporating temp. | -15℃ | Ice tube diameter | Φ22mm/28mm/35mm |

| Condensing Temp. | 40℃ | Ice length | 30 ~ 45MM |

| Total Power | 36.75kw | tube ice weight density | 500~550kg/m3 |

| Compressor Power | 63KW | Evaporator type | Stainless steel seamless steel pipe |

| Ice cutter Power | 2.2KW | Ice tube material | SUS304 stainless steel |

| Water pump Power | 2.2KW | Water tank material | SUS304 stainless steel |

| Cooling tower power | 2.25KW | Ice cutting blade material | SUS304 stainless steel |

| Water pump power of cooling tower | 7.5KW | Dimension of compressor unit | 2300*2000*1800mm |

| Refrigerant gas | R404A/R22 | Dimension of tube ice evaporator | 1600*1400*4600mm |

| Item | Name of Components | Brand Name | Original Country |

| 1 | Compressor | BITZER/HANBELL | Germany/Taiwan |

| 2 | Ice Maker Evaporator | ICESNOW | China |

| 3 | air cooled condenser | ICESNOW | |

| 4 | Refrigeration components | DANFOSS/CASTAL | Denmark/Italy |

| 5 | PLC Program control | SIEMENS | Germany |

| 6 | Electrical components | LG (LS) | South Korea |

| 7 | Touch screen | WENIVIEW | Taiwan |

Tube ice machine-Bitzer compressor

To facilitate installation and shipment, Icesnow large capacity tube ice machine features modular design. The whole unit consists of 3 parts, compressor module, evaporator module and cooling tower module. Compressor module: Compressor, water condenser, reservoir, liquid receiver, oil separator, and electric control box are all installed on the steel frame.

Tube ice machine-Electronic components

(1) The tube ice machine adopts the integrated design, compact structure, easy installation and use;

(2) PLC man-machine interface computer module, ice making and ice automatically switches off, save time and effort;

(3) All equipment using CAD, 3D simulation assembly, arrangement of equipment parts and accessories, pipe to more

reasonable,compact structure and not crowded, operation, maintenance more human;

(4) According to different working condition of customized, non-standard tube ice machines can be made.

Tube ice machine-Water cooled condenser

(1) Tube ice machine, operates on an intermittent cycle, for example 18 minutes ice making and 3 minutes ice harvesting per cycle based on external diameter of 35mm specification ice tube;

(2) The internal diameter of tube ice can be adjusted according to ice making time;

(3) The tube ice machine evaporator employs SUS304 material and the heat exchange tube is designed at the most optimized thickness, combined with specialized heat treatment processing technology, which makes the best use of heat conductibility.

Icesnow Tube ice machine-Cooling tower

All small type water-cooled tube ice machines are designed as integral type. Water in the cooling tower is delivered by pump into condenser. The temperature goes high after it exchanges heat with refrigerant. Then the high temperature water is delivered back to the top of cooling tower for cooling. The cooled water recycled to the sunk below and be used again. In the process of heat dissipation, some water will be evaporated into the air. Hence, cooling tower needs constant water supply when ice machine is running. Cooling tower usually be placed at outside ventilation place. Some water and vapor will be ejected out around of the cooling tower. So please pay attention to its environment when install it.

Icesnow Tube ice machine-Evaporator

(1) The tube ice maker evaporator using high quality stainless steel 304 and other materials processing, meet international health standards;

(2) we can do the OEM and follow you requirements for the trade mark . If you need ,we can produce evaporative condenser according to your design or conditions .The customized packing for tube ice machine condenser is also at your service.

Q1: Are you a factory or trading company?

A:We are a factory.

Q2: Where is your factory located?

A:Our factory is located in Shenzhen city,China.

Q3: What is the raw material of your products?

A: As general, the raw material of steel is stainless steel 304# .

Q4: What is the term of payment?

A:As general, less than 5000 USD ,100%T/T in advance. More than 5000 USD ,30%T/T in advance, balance before shipment.

Q5: What is the delivery time?

A:It depends on the order quantity and racking types. If you purchase our standard machine,the delivery time is around 7days.

Q6: Which port will be used as loading port?

A:Shenzhen port or Nansha Port is recommended.

Q7: May I know the status of my order?

A:Yes.We will send you information and photos at different production stage of your order. You will get the latest information in time.

Q8: Can we put our own logo on the machine?

A:Yes,we can do OEM for you.

Q9: About the warranty?

A: One year for the whole unit. During warranty time, we offer parts for free(except consumption parts like rings and beaters).

Product detail pictures:

Related Product Guide:

We persist with the principle of "quality 1st, assistance initially, continual improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the standard objective. To great our service, we present the products and solutions while using the very good top quality at the reasonable cost for High reputation Cube Ice Maker - Full Automatic 20T/day tube ice maker – Icesnow , The product will supply to all over the world, such as: Curacao, Jamaica, Jersey, With many years good service and development, we have a qualified international trade sales team. Our goods have exported to North America, Europe, Japan, Korea, Australia, New Zealand, Russia and other countries. Looking forward to build up a good and long term cooperation with you in coming future!

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!