ICESNOW 5Ton/Day Seawater Commercial Flake Ice Maker Machine For Ice Making

1.The sea water flake ice machine is divided into two forms for marine and land use.

2.The user directly extracts seawater ice-making and condenser circulating water from the sea.

3 .Referance power supply is dynamice electricity with 380v /50HZ, however, If necessary, It can be changed into 60hz/220v/200v/440v/400v/415V/480V according to different requirement of clients.

4.Refrigerant gas: R22/R404A

5.whether the spare parts are easy to find in locally

yes, we use famous and steady refrigeration components and it is also common model in locally and way to find and replace.

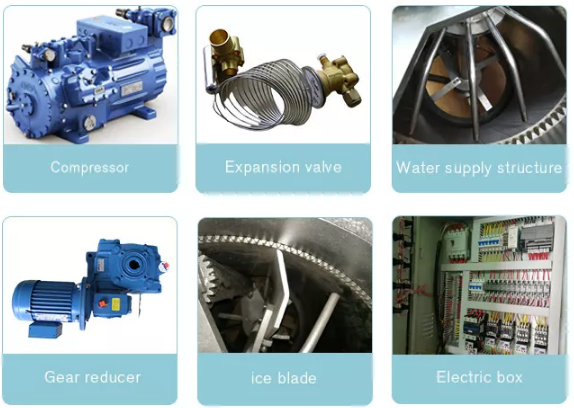

6.compressor: Refcome Compressor

1.The ice produced is in the form of flakes, the thickness can reach 2.5mm, it is dry without powder, and the ice temperature can reach -10℃;

2.The material used for the flake ice evaporator is stainless steel and anti-corrosion alloy aluminum, and the service life can be as long as 18 years;

3.Cooling type: water cooled

4.Anti-shake design, could bear 30 degrees tilting on-board

5.Daily capacity: 5 tons flake ice in 24 hrs

1.No need for personnel operation, one-key control, automatic monitoring, no need for frequent maintenance, which greatly saves manpower and material resources.

2.Strong and Durable parts.All compressor and refrigerant parts are world first class.

3.Low energy consumption.Energy consumption saving reaches more than 30% compare with traditional equipment.

4.High quality material.The evaporator drum are made of stainless steel 316 material,which is anti-rust and anti-corrosion.

5.316 Stainless steel:

The seawater flake ice machine is made of anti-corrosion 316 stainless steel, could be installed on board directly, the inclination angle could reach 35℃ degrees above,while keeping water circulating without over-flowing, keeping machine running normally. Using sea water to make ice directly, then the ice drops into cabin. This will reduce the loading of the boat, save energy.

6.Good quality and advanced technology:

The ice drum internal use spiral channel structure designs and the V-Shaped groove welding technology that save energy by more than 5% to 8% compared with the same type machine in the industry. The center layer use the baking paint treatment, to shape and solid the welding point on the flow channel, and no refrigerant leakage occurs.

Why Choose Us?

1.Icesnow have strong R&D engineer team and supply high quality and steady products.

2.Icesnow have strict products quality control system

3.Icesnow unique flake ice evaporator processing technology

4.Icesnow have unique technology on the ice scrape blade.

1. What's the voltage of the ice machine?

Answer: Standard voltage: 380V-50Hz-3phase, other speccial voltage can be customized also, like: 220V-60Hz-3pase, 415V-50Hz-3phase, 480V-60Hz-3phase.

2. How about the cooling way?

Answer: Usually small ice machines are air cooling, medium and large ice machines are water cooling.

3. How long is your warranty?

Answer: 2 years, and Lifelong after-sales service and technical support.

4.Do you test the ice machine in your factory?

Yes, ice machine leaves factory with carefully examination after it was produced for 3 to 5 days. And when we install them at customer’s factory, we retest the ice machines.